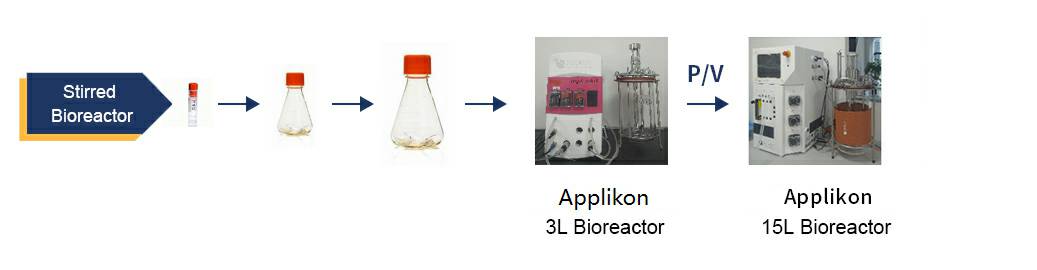

TOP cloning bioreactor culturing evaluation, 3-15L scale culturing process development system.

The novel bio-reacting and amplification system isjointly developed between Canton Biologics and the world's top bioreactor supplier Kuhner. It is more suitable for shear-sensitive protein manufacturing, providing a more stable culturing environment for easily degradable and easy-to-aggregate proteins. The system has excellent scale-up consistency from lab scale to batch manufacturing scale.

Please Contact Us for Further Service Details and Quotations!

Copyright © 2021 皇冠8xmax官网(中国)有限公司 ALL RIGHTS RESERVED